Foamed polyethylene (EPE) is waterproof, mechanically resistant, it protects against repeated shocks, extremely chemically resistant and fully recyclable. It is used primarily for protective packaging of furniture, electronics, automotive parts and other products.

Polyethylene Foam

Advantages of foamed polyethylene

- looks impressive,

- excellent flexibility, low thermal conductivity

- chemical resistance,

- mechanical shock resistance,

- health and environmental safety,

- easy workability and durability,

- fully recyclable (contains no halogens, sulphates, silicones, cadmium, lead ...)

Typical applications of polyethylene foam

- product protection against abrasion,

- protection of product edges and corners,

- product spacing,

- thermal insulation, floor covering underlay,

- thermal and acoustic insulation of roofs and walls of buildings,

- protective thermal insulation for greenhouses, hotbeds and stables,

- thermal insulation of pipeline systems,

- production of mats.

Technical specification of polyethylene foam

- polyethylene foam can be supplied in widths and lengths according to customer's requirement

- polyethylene foam thickness up to 100 mm,

- on request it is possible to produce sheets, bags and edges from this material.

| PE Foam - roll | PE Foam - sheets |

| - Thickness: 0,8 - 10 mm - Width: 1000 až 1500 mm - Length: 50 - 700 m - Density: 18 - 21 kg/m3 |

Thickness: 0,8 - 100 mm Width: 120 až 1000 mm Length: 150 až 2000 mm |

PE Foam - Bags |

|

|

- Thickness: 0,8 - 2 mm |

|

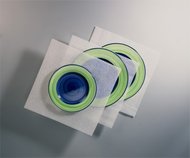

Edges of foamed polyethylene (EPE)

Edges of foamed polyethylene (EPE)

- protection of corners and edges of products sensitive to damage (sheet glass, furniture, sharp edges .....)

- lightweight, flexible, resistant to damage, moulded,

- suitable for multiple use,

- produced in standard density of 30 to 45 kg/m3,

- possibility to produce customized corner fittings,

- can be used several times in succession,

Types of polyethylene foam:

PLASTOCELL – Foamed Polyethylene (EPE)

- it is a foamed PE laminated with HDPE with a thickness of 10 micron,

- thickness: 1 mm to 5 mm,

- roll width 1000 mm, 1200 mm, 1500 mm,

- roll length 500 m,

- other possible versions: bags.

STRATOCELL® – Foamed Polyethylene (EPE)

- low-density unmeshed polyethylene foam, ideal for multiple product protection

- absorbs repeated impacts on the product and in doing so it does not significantly lose its protective ability.

- layered lamination - application of heat

- standard series: Stratocell® E a Stratocell® S

- special series: Stratocell® FC, Stratocell® 35, Stratocell® 65 and Stratocell® 100.

- standard sheet dimensions: 1200 mm x 2000 mm

- optional sheets can be supplied with a length of 1500 to 3000 mm

- thickness: 25 - 50 mm.

CELL-AIRE – Foamed Polyethylene (EPE)

- production of low density PE (LDPE), without admixture of substances based on CFCs;

- reusable and recyclable,

- having enclosed cells without mesh structure,

- supplied thicknesses: 0.7 mm, 1.0 mm, 1.5 mm, 2.5 mm and 4.0 mm

CUSHION-PLY – Foamed Polyethylene (EPE)

- high-performance low-density PE foam

- can replace polyurethane sheets, expanded polystyrene and cardboard folding boxes

- supplied in a thickness of 40 mm, density of 16 kg/m3

- can be pressed and welded with hot air.

Send your inquiry to demand@tart.cz